Inspection Services

Inspection, Surface Preparation, Coating, Repairing & Various Types Of PF NDT Works

Qualified Personnel in Inspection

- Welding inspectors with CSWIP and AWS certifications

- NDT Inspectors with PCN and ASNT certifications

- Painting Inspectors with NACE and SSPC certifications

- Rope Access Technicians with IRATA Level I, II & III

Third Party Inspection

- Visual inspection on fabricated structural welds.

- Witnessing and Qualifying Welding Procedure Qualification Record (WPQR).

- Witnessing and Qualifying Welding Procedure Specification (WPS).

- Certifying the welders by welder qualification test (WQT).

- Raw material inspection.

- Dimensional inspection.

- Witnessing and approving Pneumatic Test.

- Witnessing and approving Hydro Test.

- Painting Inspection.

- Reviewing of Radiographs.

Ultrasonic Test

- Ultrasonic thickness gauging on Hull survey on different types of ships and oil rigs, pressure vessels, oil storage tanks, and power boiler pipes.

- Ultrasonic test on welds of structural, pipeline and pressure vessels.

- Ultrasonic test on cast iron valves and rollers.

- Ultrasonic test on forged bars and forged valves.

- Ultrasonic test on bonded material of bearings.

- Ultrasonic test on seamless pipes to detect internal discontinuities.

- Ultrasonic test to detect lamination type discontinuities on steel plates.

- Ultrasonic thickness gauging for base line study on offshore platform piping and pressure vessels.

Magnetic Particle Test

- Wet method of MPT on welds of structural, pressure vessel, storage tanks and power boiler pipes .

- Dry method of MPT on casting valves and casting rollers.

- Fluorescent method MPT on forged valves and welds of pressure vessels.

Radiography Test

- Radiography test on welds of Oil storage Tanks, Pressure Vessels,

- Refinery Piping's and Steel Structural .

Magnetic flux leakage (MFL)

- To Detect corrosion on the bottom plates of storage tanks

Dye Penetrant Test

- DPT on welds of pressure vessel and pressure pipes.

- DPT on various types of machinery components.

- DPT on welds of stainless steel storage tanks for chemical.

- Fluorescent DPT on turbine blades.

Advance NDT Phase Array

- Corrosion survey and fatigue cracks inspection on Natural Gas lines.

- PA Inspection on pressure pipe lines and pressure vessels.

- PA Inspection on forged Marine Engine Shafts.

- PA Inspection on Heavy Wall Thickness Spheres.

- PA inspection on welds of sub-sea pipeline.

- corrosion survey and HIC survey on Plant Equipment .

- Analysing of Phased Array Data in Tom view software.

Time- of- Flight- Diffraction TOFD

- TOFD on welds of LNG sphere

- TOFD on welds of heavy wall thickness of pressure piping.

- TOFD on welds of sub-sea pipeline.

Long Range Ultrasonic Test LRUT

- Insulated Pipe in Refineries

- Offshore Pipeline Risers

- Cased Road or Railway Crossings

- Loading Lines and associated Pipe work

- Tank Dyke Pipeline Crossings

- Above Ground or Buried Flow Lines

- River or Bridge Pipeline Crossings

- As part of ECDA & ICDA Methodologies

Eddy Current

- To Detect surface crack of the Materials

- On Internal Tubes of Heat Exchangers

Destructive Test

- Tensile Test

- Impact Test

- Bend Test

- Hardness Test

- HIC Test ( Hydrogen Induced Crack)

Chemical Analysis

- To analyse the elements in the material

- PMI ( Positive Material Identification)

Quality Training

NDT has strong in-house quality training

program. Continuous training is imparted to all the

staff in their respective fields to meet the growing

need of customers and international standards. Our

quality-training program is based on the principle of

continuous improvement.

Our staffs are trained in various disciplines and

special training is provided for specific projects, when

required.

QA/QC Area

For any test result to be valid and reliable, careful monitoring and implementation of QA/QC procedures are required. One key element of successful quality assurance is regular participation of a laboratory in a national and/or international Proficiency Testing Program (PTP) program. NDT International participates regularly in national and international PTP with most results exceeding the minimum requirements of acceptance.

Strength of Our QA/QC Program

Sampling Procedures

- Calibration Checks and Frequencies

- Analytical Procedures, Revisions and Validations

- Reporting

- Internal Quality Control Checks

- Internal Performance and System Audits

- Internal Training Programs

- Assessment of Precision and Accuracy

- Corrective Action Reports (CARs)

- Non Conformance Reports (NCRs)

- Management Review Meeting (MRM)

- Internal Quality Audit (IQA)

NDT Major Diversified Divisions

- Indoor Air Quality Division (IAQ)

- Mechanical/Material Testing Division

- Metallurgical Failure Investigation Division

- Full Ring / Coating Testing Facility

- NDT, Heat Treatment & Inspection Division

- Third Party Inspection (TPI) Services Division

Mechanical Testing/Metallurgy Testing

NDT International has the capability to cater to the Mechanical Testing requirements of a wide range of materials and products.

The testing capability and experience are recognized by reputed classification societies and third party inspection agencies.

Mechanical/Material Testing

Our Mechanical Testing Division is equipped to perform Mechanical Testing for wide range of materials and products. The tests we perform include:

- Tensile Test

- Impact Test

- Macro Examination

- Compression Test

- Nick Break Test

- Flattening Test

- Crack Tip Opening Displacement (CTOD)

- Hot Tensile Test

- Bend Test

- Micro Examination

- Fillet Fracture Test

- Proof Load Test

- Flaring Test

- Hardness Test (Brinell, Vickers and Rockwell)

Metalurgical Failure Investigation Division

NDT International offers a wide range of metallurgical services to many diverse industries supported by an experienced team of metallurgical engineers, trained technicians and modern equipment. We offer a spectrum of metallurgical testing and it includes:

- Root Cause Metallurgical Failure analysis

- Replica Metallography

- Stereo and Optical Microscopy

- Grain Size Measurement

- Point count Method for Delta Ferrite

- Micro Structural Analysis

Coating Testing Facility

We provide a comprehensive list of coating test which is mainly applicable to pipes and field joint coatings. The test we perform include:

- Cathodic Disbondment Test

- Holiday Detection

- Tensile Test

- Water Absorption Test

- Impact Strength

- Heat Ageing

- Pull Off Adhesion Strength

- Lap Shear Test

- Porosity Test

- Hot Water Immersion Test

- Flexibility Bend Test

- Coating Thickness Verification

- Peel Off Adhesion Strength

- Indentation / Penetration Resistance

- Coating Resistivity / Electrical Insulation Resistance Test

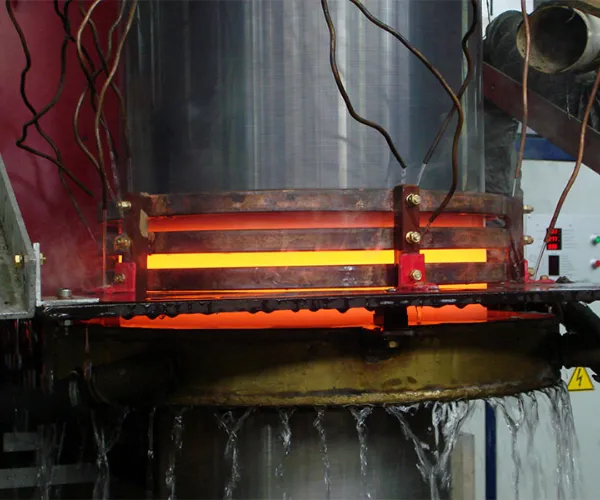

NDT Heat Treatment & Inspection Division

NDT International has an independent NDE & Inspection and Heat Treatment services division providing full range of NDE and inspection services locally and internationally. Our extensive list of technical services includes a full range of accepted NDE methods, QA/QC function, welding & coating inspection.

In Service Conditioning And Monitoring

Our Mechanical Testing Division is equipped to perform Mechanical Testing for wide range of materials and products. The tests we perform include:

- Pipeline

- Plant Piping

- Storage Tank Farms

- Heat Exchangers, Columns, Silos

- Pressure Vessels

Service Provided

Ultrasonic Testing

- Manual UT

- Condition monitoring thickness surveys

- UT Mapping for Petrochemical, Equipment and Piping

Radiographic Testing

- X-Ray directional

- Profile radiography

- Pipeline internal X-ray crawlers for pipe dia 6’’ to 60’’

- Gamma ray iridium – 192 and selenium - 75

Advanced ultrasonic Testing

- Phased array ultrasonic taesting (PAUT)

- Time of flight diffraction testing (TOFD)

- Long range guided wave ultrasonic testing (LRUT)

- Short range guided wave ultrasonic testing (SRGUT)

- Internal rotary inspection system (IRIS)

Magnetic Particle Testing

- Magnetic particle inspection

- Fluorescent method

Pre & Post Weld Heat Treatment

- Local pre and post weld heat treatment

- PWHT utilizing electrical resistance coils and temporary furnaces

Electromagnetic Test (ET)

- Eddy current test (ECT)

- Near field test (NFT)

- Remote field testing (RFET)

- Alternating current filed measurement (ACFM)

- Saturated low frequency eddy current (SLOFEC)

Other Services

- Liquid penetrant testing (PT)

- Positive material identification

- Field hardness testing

- Acoustic emission testing (AET)

- Visual and optical testing (VT)

- Digitization of radiographs

- Ferrite content measurement

Leak Testing

- Vacuum box testing for tank floor

- Holiday detection

Third Party Inspection(TPI) Services Division

NDT International has an independent Third Party Inspection Services (TPI) division providing services locally and worldwide to ensure and verify quality and compliance to the clients’ requirements as well as to international standards.

Our TPI services have various approvals and registrations from internationally recognized entity which include Oil & Gas sector, EPC & construction companies. Quality management system for TPI Division of NDT International is certified in accordance with ISO 9001:2008.

NDT International maintains a worldwide staff of qualified and experienced inspectors through our associates. We provide global coordination of inspection activities and a uniform inspection approach. Our TPI inspectors are committed to providing consistent quality service at all times. Our global reach allows us to mobilize qualified staff and reduce overall inspection costs to our clients.

NDT International provides inspection services to all of the main sectors and industries including:

- Power Generation and Distribution

- Chemicals & Petrochemical

- Manufacturers

- Refineries

- Utilities

- Project Management Services for Civil, Mechanical, Electrical and Instrumentation

- Fertilizers and Pharmaceuticals

- Mining

- Pipelines

- Oil & Gas

- Project HSE and QA/QC activities

We are actively involved in Third Party Inspection during:

- Investigations and Review of Failure

- API Introductory Trainings

- Supply of Project Technical Resources

- Calibration of Storage Tanks

- Specialized NDE (PAUT, TOFD)

- NDT Training and Certification

- Tubular Inspection and Integrity

- Plant Integrity Services

- Lifting Equipment Inspection and Certifications

- Conventional NDE (Workshop and at Site)

- Provision of QA/QC and Inspection Personnel

- Supply of ASNT NDT Level III Certified Personnel

- Source Inspections during Fabrication of Pressure System Modular and Equipment

In Service Inspection

- Re-qualification of Plant Equipment, Piping

- Maintenance Inspection

Inspection During New Fabrications

- Storage Tanks

- Compressors

- Valves and Fittings

- Pumps & Blowers

- UPS & Transformers

- Generators

- Turbines

- Pressure Equipment, Piping & Pipelines

- Instrumentation and Control Systems

Manpower Deployment

- Witnessing Performance Test

- NDE Crew

- Project Management

- Expediting Services

- NDT Personnel Qualification

- Supply of Technical Resources & Manpower

- Qualification of Welding Procedures and Welders